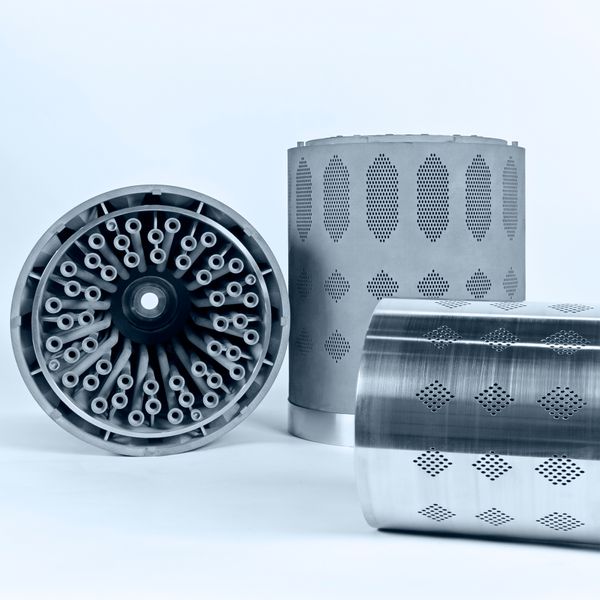

A precision stainless-steel sheet bending part

The client

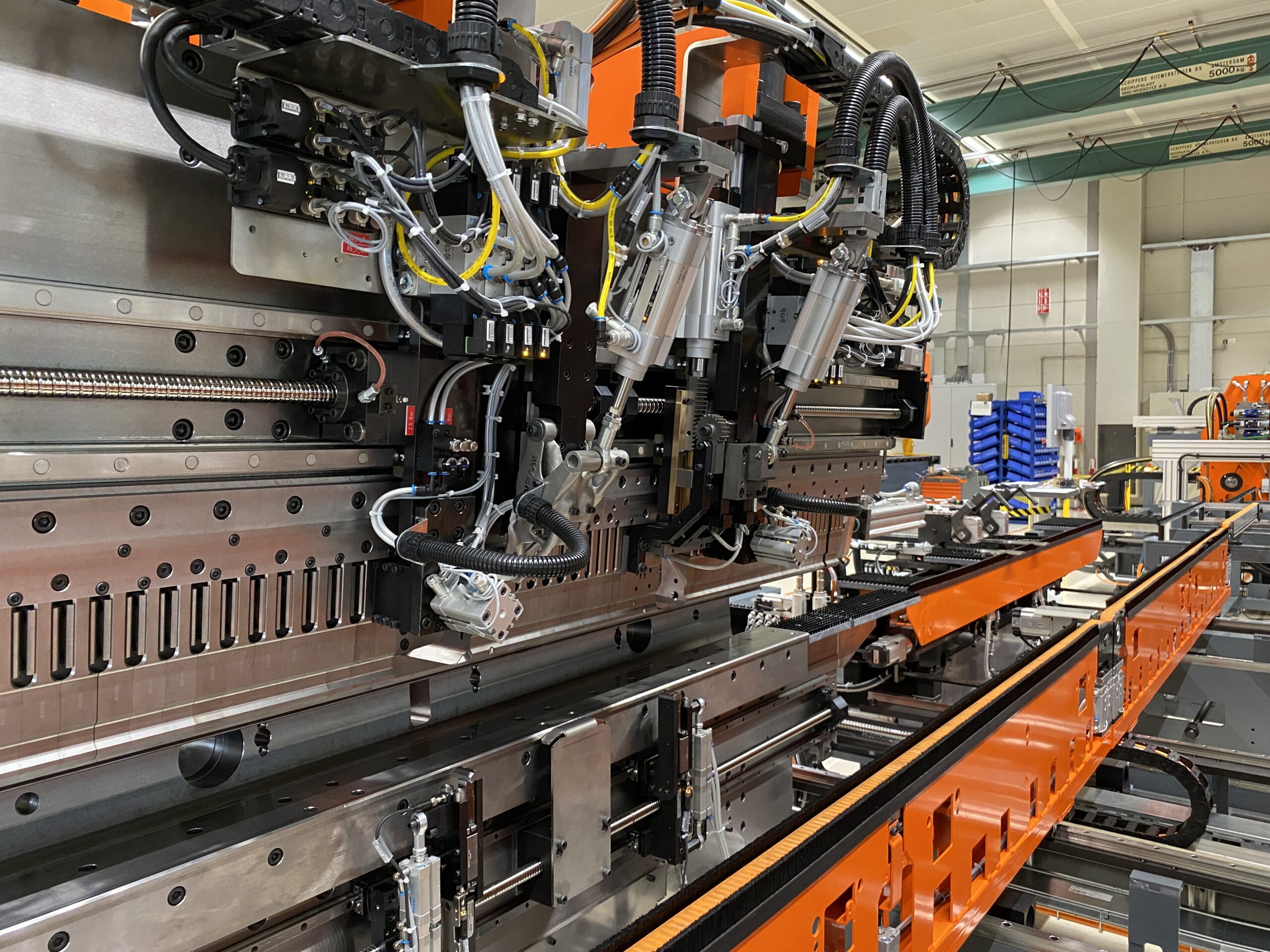

At Additive Center, we specialize in advancing Additive Manufacturing (AM) technologies for various industries by integrating AM into existing manufacturing processes. We’ve partnered with WEMO Special Projects, a leading provider of custom production lines for sheet metal processing to explore how AM can transform their production lines by introducing smarter machines and components to optimize machinery productivity, integrate lightweight parts, and reimagine design approaches. Additive Center is proud to drive innovation and deliver value-added solutions to partners like WEMO Special Projects.

Information

Client:

WEMO

Technology:

SLM – Selective Laser Melting

Material:

Stainless steel 316

Categorie:

Sheet metal production lines

The challenge

The part that we identified that could be improved was the stainless-steel sheet bending part. To eliminate tolerance build-up, our engineers explored a robust monolithic design capable of accommodating various variable inserts. The part should rotate around a connected axis at the top and be securely fixed as per the tool or insert. Specific surface areas of the part must sustain functionality.

We utilized Apex Generative Design software by Hexagon to sculpt the part based on functional features and applied forces. The final geometry preserves the functionality of the original features, ensuring sufficient material connection to support the applied forces. The optimized part underwent stress and deformation analysis, resulting in an improved, cost-effective structure. The refined design was manufactured using Selective Laser Melting (SLM) – Additive Manufacturing technology.

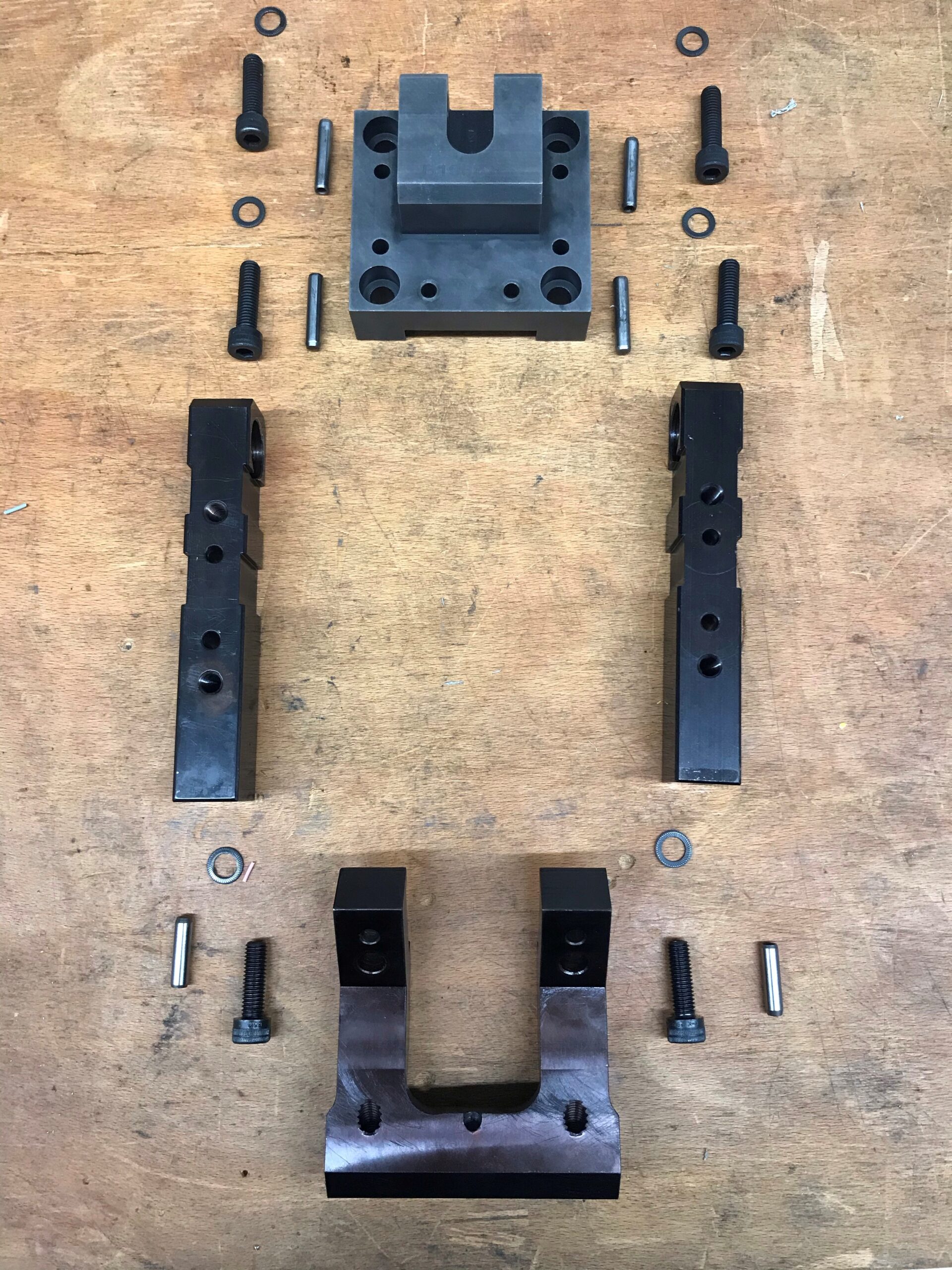

Original

In their line of heavy-duty sheet bending machines is a part that holds the various tools used for bending. Conventionally constructed out of 4 CNC-milled elements, this part is consecutively put together with pins, washers and screws making an assembly of 22 parts in total. The tolerance build-up in this assembly makes the milling process both complicated and costly. And that’s exactly where Additive Center could add some value!

Redesign

A single-part solution, designed to not only reduce costs and lead time, but also to transform the way you approach production. Crafted with stainless steel using cutting-edge 3D printing technology, our solution offers unmatched efficiency, precision, and quality, delivering exceptional results that will elevate the production process to a new level of excellence.

The advantages

Reduced costs

Significantly cheaper to produce

Easy assembly

There is no need to piece together 22 different parts.

Reduced weight

60% weight reduction

Single material

Streamlining the supply chain with organic, monolithic design to reduce material waste.