From prototype to industrialization!

The client

JHT is a global, customer-centric company specializing in coating and engineering. They offer comprehensive solutions for coating, laminating, and impregnating systems. Additionally, they undertake retrofitting of old systems and the prodution of unique components

Information

Client:

JHT coating

Technology:

SLM – Selective Laser Melting

Material:

Stainless steel 316

The challenge

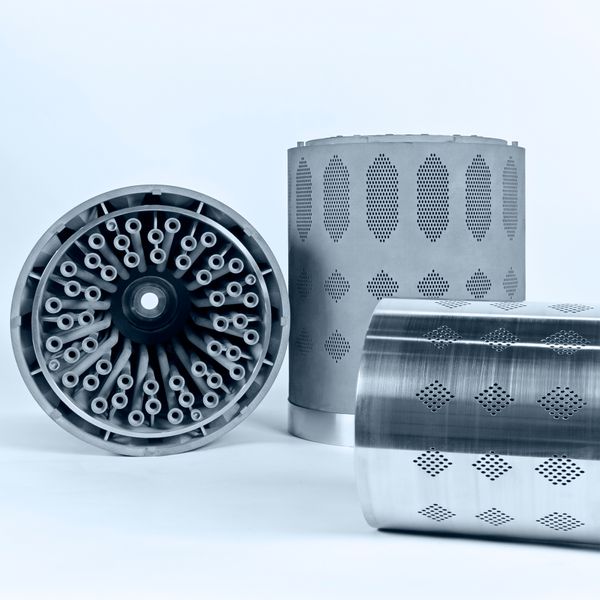

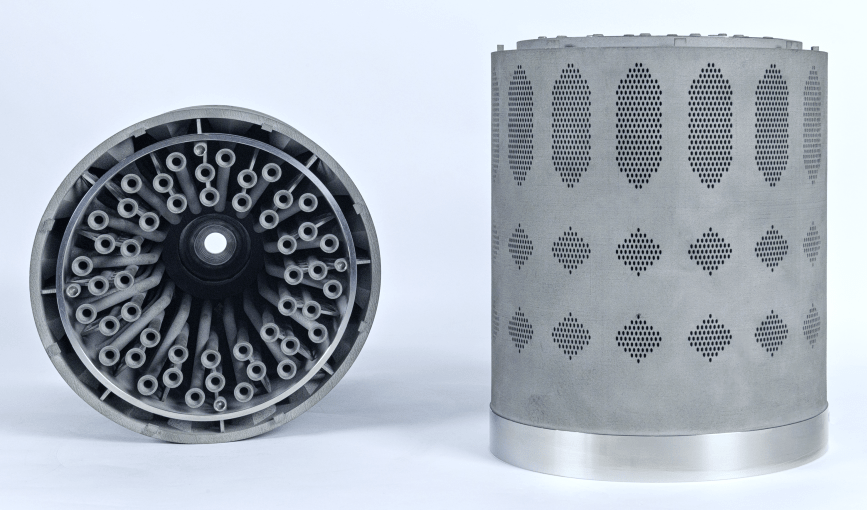

JHT, in partnership with a university, innovatively crafted a prototype for a new kind of roller: a stainless steel, segmented 3D-printed roller with internal vacuum channels. The pressing issue was the industrialization of this prototype. The aim was to figure out a manufacturing process that was cost-effective, maintained quality standards, and optimized the initial design.

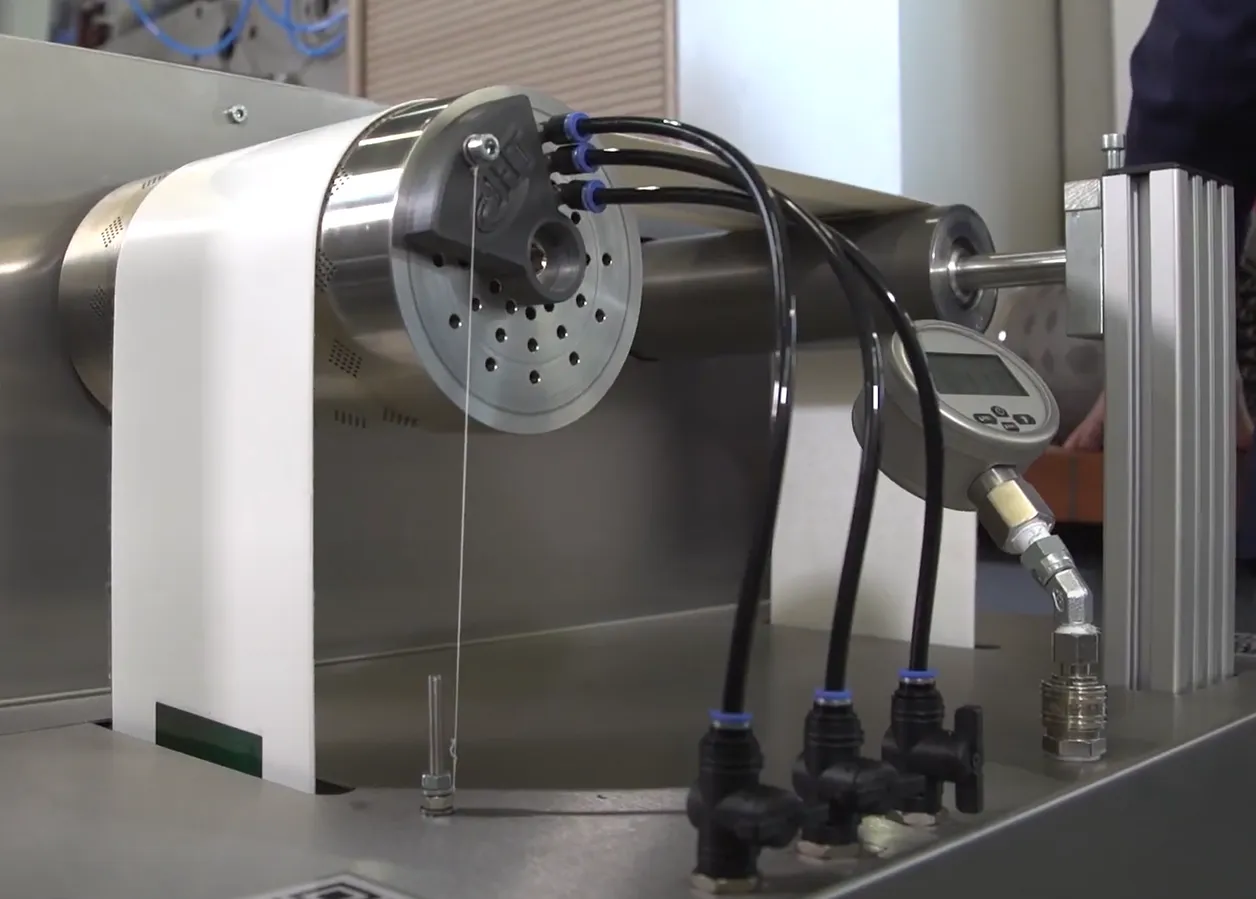

Close collaboration was at the heart of the industrialization process. We worked hand in hand with JHT and leveraged our extensive supplier network to devise a scalable industrial solution, allowing JHT to commercialize their pioneering product. By fine-tuning the design for manufacturability in conjunction with the customer and ensuring rigorous quality checks with suppliers, the project successfully transitioned from concept to market-ready product. With the build job simulation of Simufact Additive (Hexagon Software) it was possible to get an estimation of final stresses and displacement of the part and to identify areas which could lead to critical build job failures.

The result

A component that can only be produced through additive manufacturing rather than traditional methods. Its intricate design features unique shapes that render it unsuitable for conventional manufacturing processes. This part could be fabricated in metal using 3D printing technology, ensuring all details are accurately replicated.

The advantages

Enhanced Competitiveness

With the new product, JHT improved its market position and competitiveness.

Smooth Market Entry

JHT was able to introduce their innovative product to the market without manufacturing concerns.

Assured Quality

By leveraging our qualified manufacturing network, we guaranteed the highest quality for JHT