Delivering Scaled Production with Uncompromising Precision

Table of contents

- The challenges

- Why this matters

- Our solution

- Real-world example

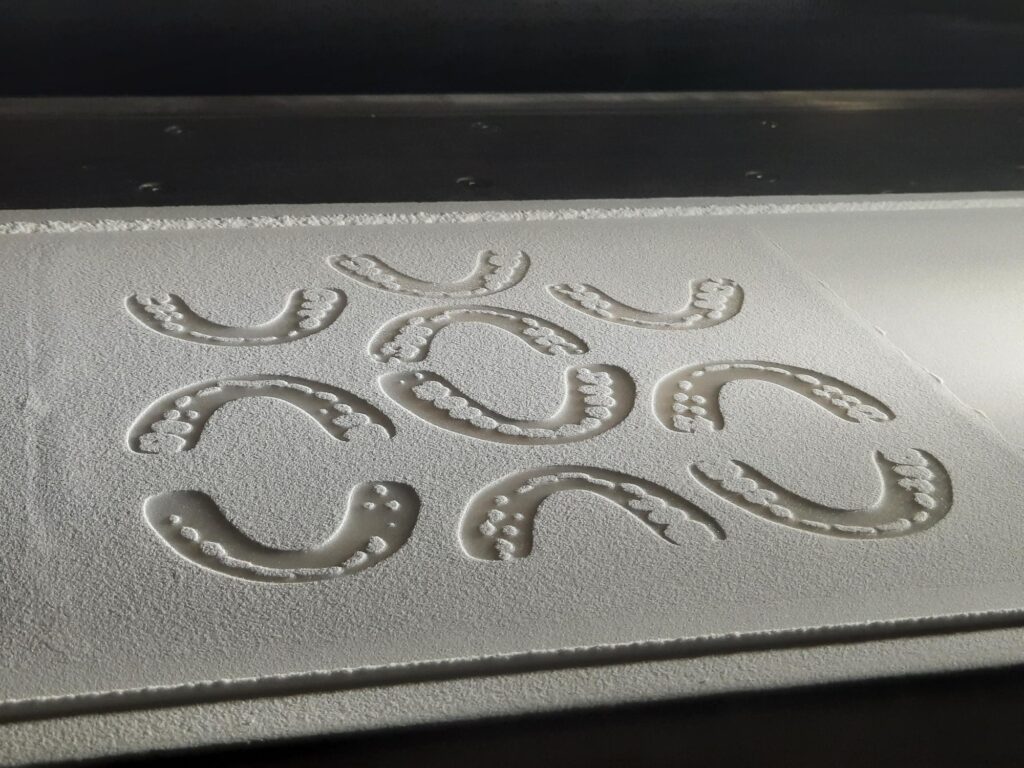

At Additive Center, we understand the unique challenges of scaling production while ensuring top-tier quality. Scaling production in traditional manufacturing often introduces inconsistencies, but with advanced Additive Manufacturing (AM) technologies, we are capable of delivering large-scale production with precision, consistency, and efficiency. Our expertise extends to high-tech industries, packaging and energy sectors where quality cannot be compromised, even when production scales up rapidly.

The challenges with scaling production

Large-scale production is often plagued by challenges such as maintaining uniform material properties, ensuring machine consistency, and managing human errors. In traditional manufacturing, scaling up often leads to a drop in quality control because of the difficulty in managing variability across machines, operators, and processes. For industries such as semiconductor manufacturing or medical packaging, any deviation in quality can lead to costly defects, product recalls, or a loss of reputation.

The Impact of Poor Quality

Inconsistent production can create waste and inefficiencies, leading to increased costs for your business. For instance, defective parts result in rework or scrapping, both of which increase material and labor costs. Additionally, if defects are not caught during production, they can cause product recalls, harming your company's reputation and eroding customer trust. This kind of failure in the supply chain can have ripple effects, delaying projects and ultimately costing millions in lost revenue.

Our Scalable Solution

At Additive Center, we leverage the most advanced AM technologies to scale production without compromising on quality. We have built automated quality control systems that monitor each phase of production, ensuring that every component adheres to precise specifications. By implementing stringent quality control measures at every step—from initial design to final product—we are able to mitigate the risks associated with large-scale production. This approach minimizes human error, ensures consistency in material properties, and provides real-time quality monitoring through data analytics. We also emphasize decentralized production, utilizing our network of global partners to ensure that parts are produced close to the point of demand, reducing shipping costs and time-to-market. This not only speeds up production cycles but also allows for faster response times to changes in market demand.

Real-World Example

For a leading medical device company, we helped reduce assembly complexity by consolidating a multi-part component into a single, 3D-printed piece. This simplification led to a 20% increase in production speed, reduced the risk of failure in high-stress environments, and minimized maintenance downtime.

Let's Work Together

Interested in scaling your production with additive manufacturing? Let's work together and find the fitting solution for you!