Bespoke Engineering to Solve Your Unique Challenges

Table of contents

- The challenges

- Why this matters

- Our solution

- Real-world example

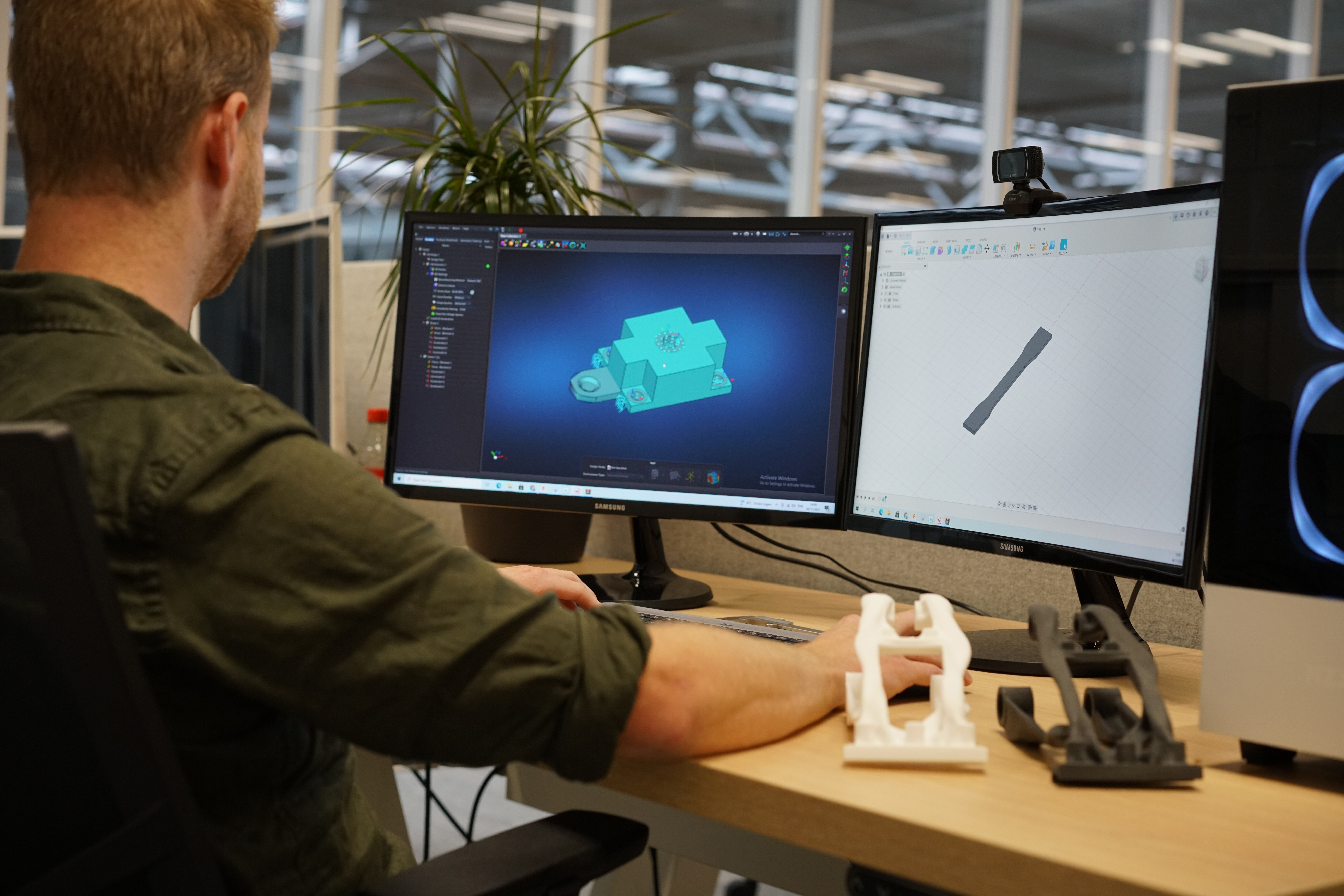

At Additive Center, we pride ourselves on delivering customized engineering solutions that are designed to meet the specific needs of your business. We understand that off-the-shelf solutions often fall short when it comes to complex, high-performance applications. This is especially true in industries like semiconductor manufacturing, where precision and innovation are critical to success. With our expertise in AM technologies, we provide tailored solutions that drive efficiency, innovation, and cost-effectiveness.

Common Problems with Standard Engineering

In many engineering projects, standard solutions fail to address the specific challenges faced by each individual business. Whether it’s dealing with complex geometries, specific material requirements, or performance constraints, standard solutions often result in inefficiencies, suboptimal performance, or worse—failure to meet project goals. This is particularly problematic in sectors like aerospace, automotive, or packaging, where the ability to innovate and customize is essential for staying competitive.

Why It Matters

When companies rely on one-size-fits-all engineering solutions, they risk facing cost overruns, project delays, and reduced performance. This impacts not only the success of the project but also the company's overall market position. Without the right tools and solutions, businesses may find themselves constrained by design limitations, inefficient processes, and a lack of flexibility in adapting to new challenges.

Our Customized Approach

At Additive Center, we collaborate closely with your engineering teams to develop bespoke solutions that are tailored to your specific needs. Our team uses the latest AM techniques, including generative design and topology optimization, to create components that meet the precise performance, material, and geometric requirements of your project. By customizing each design, we ensure that the final product not only meets but exceeds your expectations. We focus on optimizing designs for lightweighting, strength enhancement, and material efficiency, using in-depth simulations to predict the performance of each component before production begins. Our iterative design process allows for rapid prototyping and refinement, so your project stays on track and within budget.

Real-World Example

For a global packaging company, we re-engineered a customized gripper system using AM, reducing the number of parts from 10 to 1. This not only simplified the manufacturing process but also increased the system's overall durability and reliability under high-speed operation. As a result, the company saw a 15% increase in production efficiency and a significant reduction in downtime.

Let's Work Together

Interested in optimizing your parts? Let's work together and find the fitting solution for you!