Traditional design goes on a diet!

The client

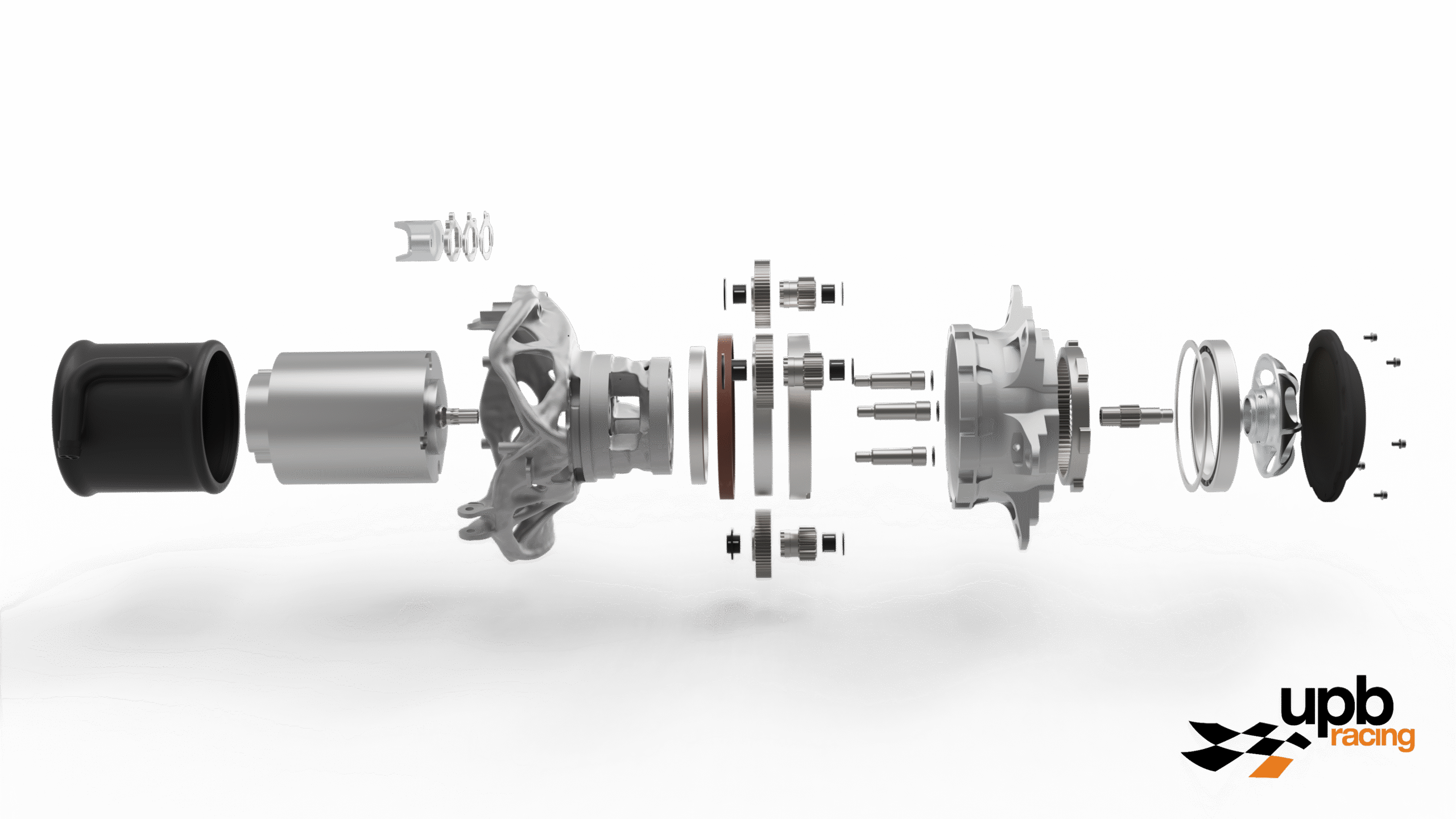

For the 2021 edition of the FormulaStudent event, UPB racing team from Paderborn university Germany were keen to try something new. Entering the new electric vehicle category posed an exciting challenge, a challenge which would allow them to rethink the race car from the ground up. In order to capitalise on this shift from ICE to EV, they would seek the aid of Additive Center in partnership with Hexagons powerful MSC simulation and generative design software to push the limits of innovation and hopefully win the race!

Information

Client:

UPBRacing

Technology:

MSC Apex generative design & FEM analysis

Categorie:

Generative design & FEM analysis

The challenge

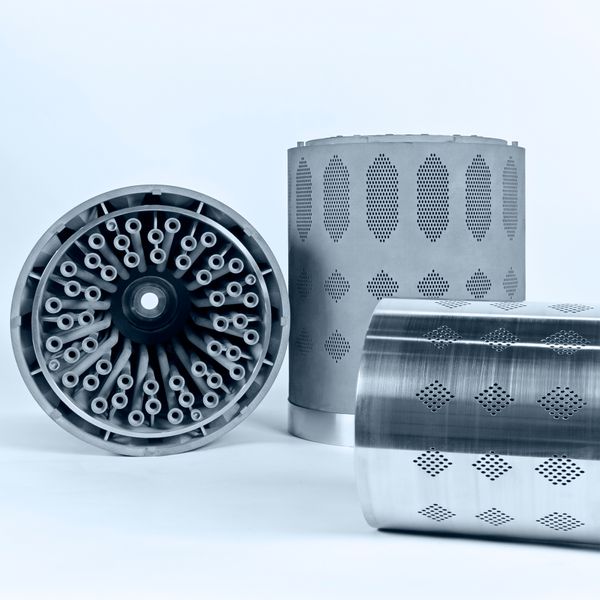

Opting for 4 independent electric motors mounted directly onto the wheels not only allowed the team to simplify the drive chain compared to traditional ICE, but also equipped them with 4-wheel drive, hopefully providing them with an edge over the competition! However, they were now faced with the complex challenge of squeezing an electric motor and planetary gear box into the already complex wheel carrier.

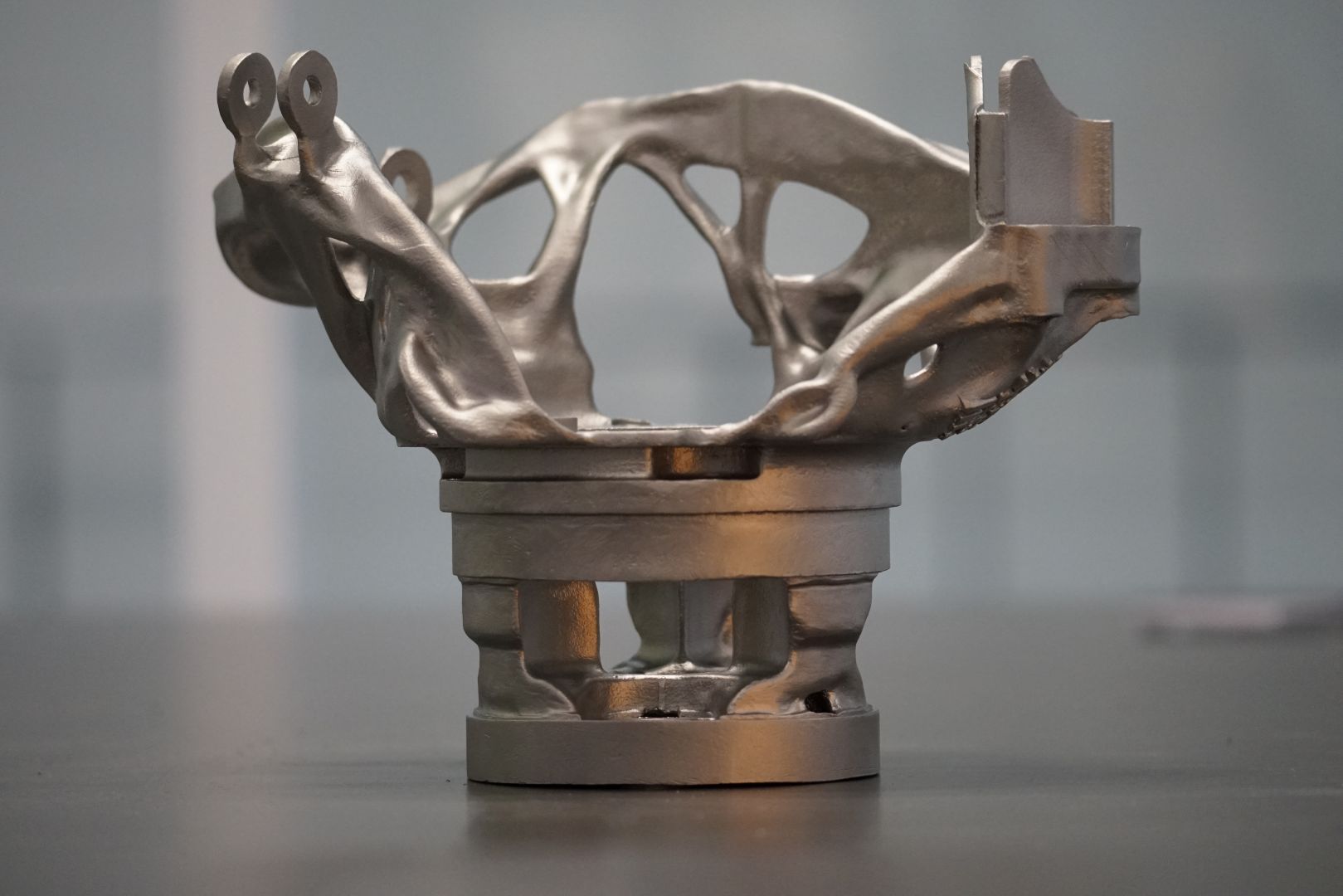

Utilising MSC Apex generative design under the guidance of Additive Center allowed the team to quickly generate different iterations to determine the most optimal design. For critical high-performance and costly components it is important to be methodical. Employing Simufact Additive from Hexagon, the students were able to simulate the additive manufactured part and check for manufacturing-induced stresses, distortions cracks and hot spots caused by the printing process. This allowed them to be confident the design would perform as intended straight from the printer.

Final Result

The advantages

Reduces material

Organic, monolithic design, preventing unnecessary use of material

Easy assembly

Assembling this part is much simpler.

Weight reduction

The weight of the part went down with 47%

Assured design

The design was first time right due to simulations and printed as one piece