Where does ASML want to go with additive manufacturing?

AM is a common theme in Tech Talks, Masterclasses, and Round Tables during Manufacturing Technology Conference 2024.

What opportunities does ASML see, and possibly also Thermo Fisher Scientific, for additive manufacturing? If you look at the schedule of the second Manufacturing Technology Conference (MTC), the potential of 3D printing must be great. Besides the number of AM technology providers exhibiting at MTC 2024, the lecture program far exceeds what you typically see at trade shows.

Over 18 companies that either offer AM technology or are involved as suppliers will participate in the second edition of MTC 2024 on April 16th. This includes the major OEMs in the field of additive manufacturing, such as GE Additive, 3D Systems, DMG Mori, Additive Industries, and Trumpf. Grindosonic will also be present. Well-known names from the supply network include the German Toolcraft, Wilting, KMWE Precision, FMI, and Hittech. Many exhibitors will have C-level employees giving the presentations, which indicates the importance they see in the Dutch market.

There is a lot of attention at MTC 2024 for additive manufacturing.

Last year, there was already a lot of attention for AM, such as at DMG Mori. This year, the offering is growing significantly.

Hittech prints and mills titanium carrier.

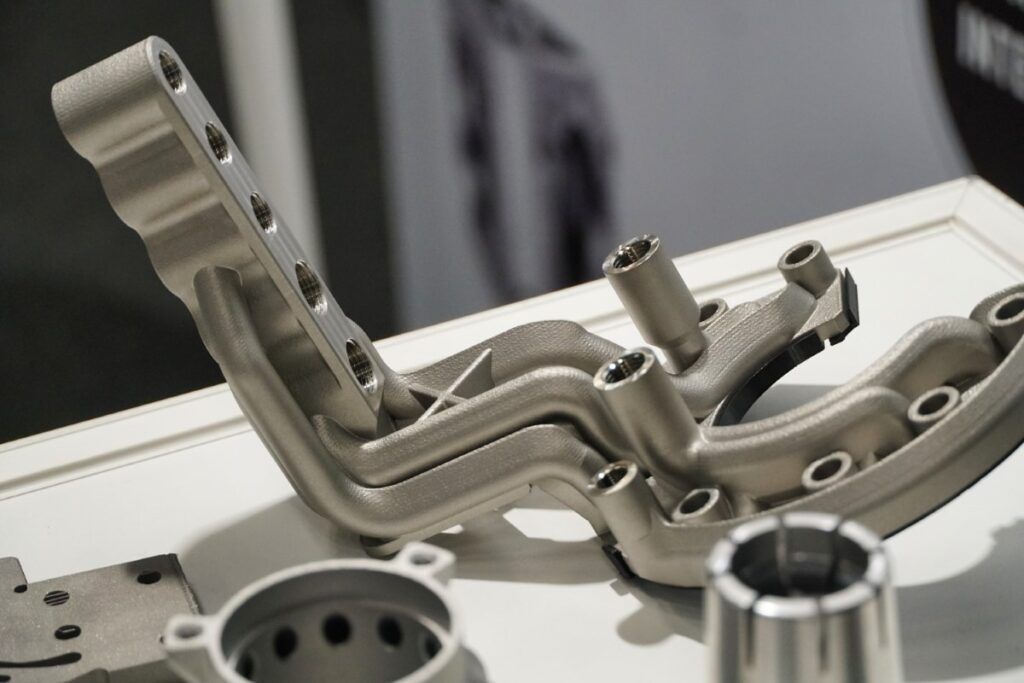

Hittech Group presents a Tech Talk together with Norsk Titanium. The two companies are working on a hybrid concept for the production of carriers for chip machines. Instead of machining 180 kilograms of Titanium into a final product of 20 kilograms, the carrier can also be printed and only needs to be milled to a limited extent. In the new edition of Solutions Magazine, Marco Verloop, COO of Hittech Group, explains why, together with partner 3T Additive Manufacturing, a joint venture for the production of ready-for-assembly parts was established. Sustainability is a reason. Making more parts in the most efficient way possible is another.

Two masterclasses around quality

This presentation is not the only one dedicated to additive manufacturing. Of the 25 Tech Talks, Masterclasses, and Round Table discussions, just under half deal with additive manufacturing. Quality assurance is a big topic. This is not only reflected in the Masterclass From AM Design to Parts Quality (in which ASML, NTS Group, Additive Center, Additive Industries, and Hexagon MI participate) but also in a second masterclass organized by Toolcraft, together with Trumpf. Toolcraft is one of the pioneers in terms of 3D metal printing and had the AM processes certified for specific applications several years ago.

GE Additive and Hexagon

The Tech Talk of GE Additive together with FMI and Landré is interesting. The American AM concern has not participated in AM events in the Benelux for a long time and now presents the advantages of AM for the high-tech industry, highlighted from the experience the concern has in the aviation industry. Mathieu Perrenou and Sven Gondron-Linke of Hexagon MI lead a roundtable discussion in the afternoon about the use of Statistical Process Control (SPC) as a quality tool in additive manufacturing.

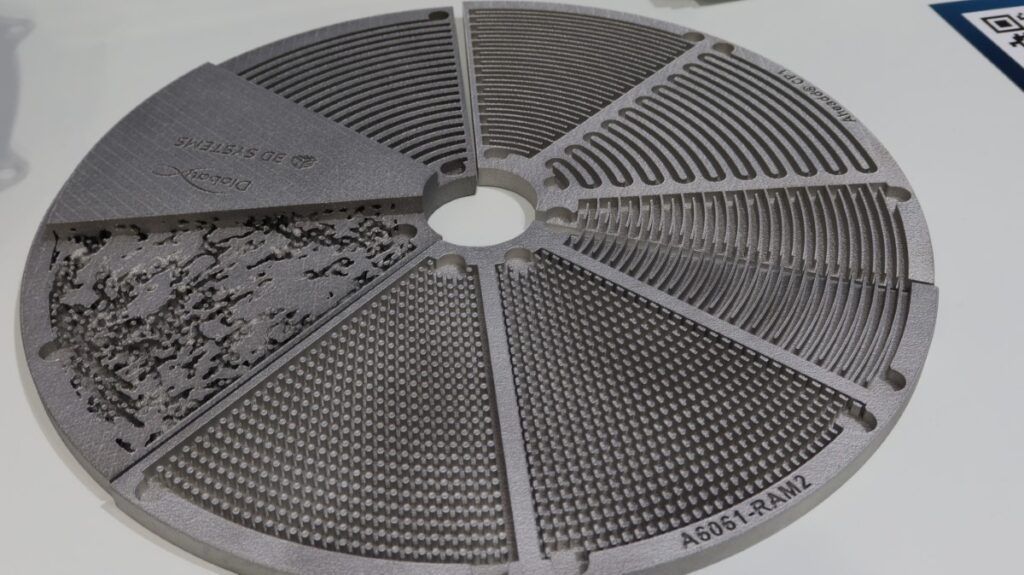

3D Systems has been exploring the possibilities of additive manufacturing in the semiconductor industry for some time now. It looks at the possibilities of integrating cooling systems, such as in this wafer chuck that it showed last year at Formnext.

How to efficiently mill AM parts

With metal 3D printing, a lot is possible. However, the parts must certainly be post-processed for the high-tech industry. Wilting, which last year took home the Knowledge Sharing award for the first time, has already gained a lot of experience in this area. One of the Tech Talks in this area this year is provided by Beijing Jingdiao Group, the Chinese manufacturer of precision CNC machining centers. Jingdiao's IMIM technology can intelligently build the coordinate system for parts with an irregular shape or uneven allowance, such as 3D printed parts. In the machine, the allowance is measured very accurately, after which the software calculates which compensation is needed to realize micrometer production. PEEK and ceramics too

Last year, Wilting won the Best Knowledge Sharing Award. Who will take the trophy home this year?

PEEK and ceramics

Exhibitors in the field of additive manufacturing include Altair, Oerlikon, Bond3D, and Lithoz and Formatec, two players in the field of 3D printing with technical ceramics. Materialise is also participating this year. MTC 2024 takes place on April 16 at NH Eindhoven Conference Centre Koningshof in Veldhoven. More information can be found here.

Adapted from: 3dprintmagazine