Sidel

Getting a grip, with 3D printing

The client

Sidel is a leading manufacturer of packaging equipment and services for various liquids. Part of the Tetra Laval Group, they specialize in handling beverages, food, and home and personal care products. Over the recent years, AC has been collaborating with Sidel to expand the application of additive manufacturing (AM) in business contexts. Our focus extends beyond the technology itself, aiming to address key business challenges such as enhancing market responsiveness, improving part availability, and facilitating the production of customized components. We excel in converting these challenges into tangible business benefits through the strategic use of printed parts.

The challenge

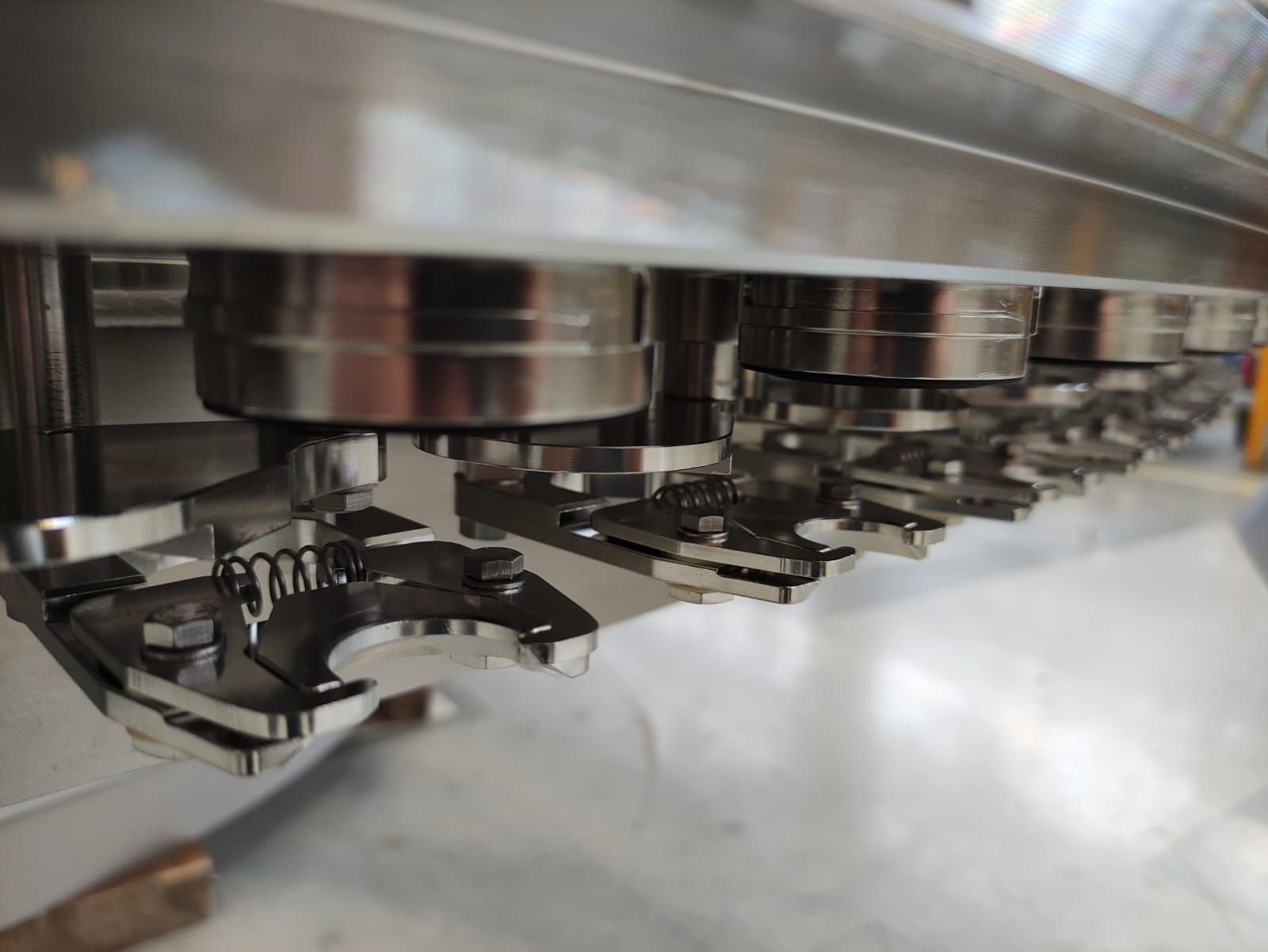

The bottle gripper is essential in Sidel's high-speed processing machinery, handling over 50,000 bottles per hour and requiring customization to accommodate various bottle sizes. Sidel aimed to transform the complex multi-part assembly into a unified single piece, while maintaining compliance with all technical standards, including stress resilience, fatigue resistance, and reliable operation during emergency shutdowns.

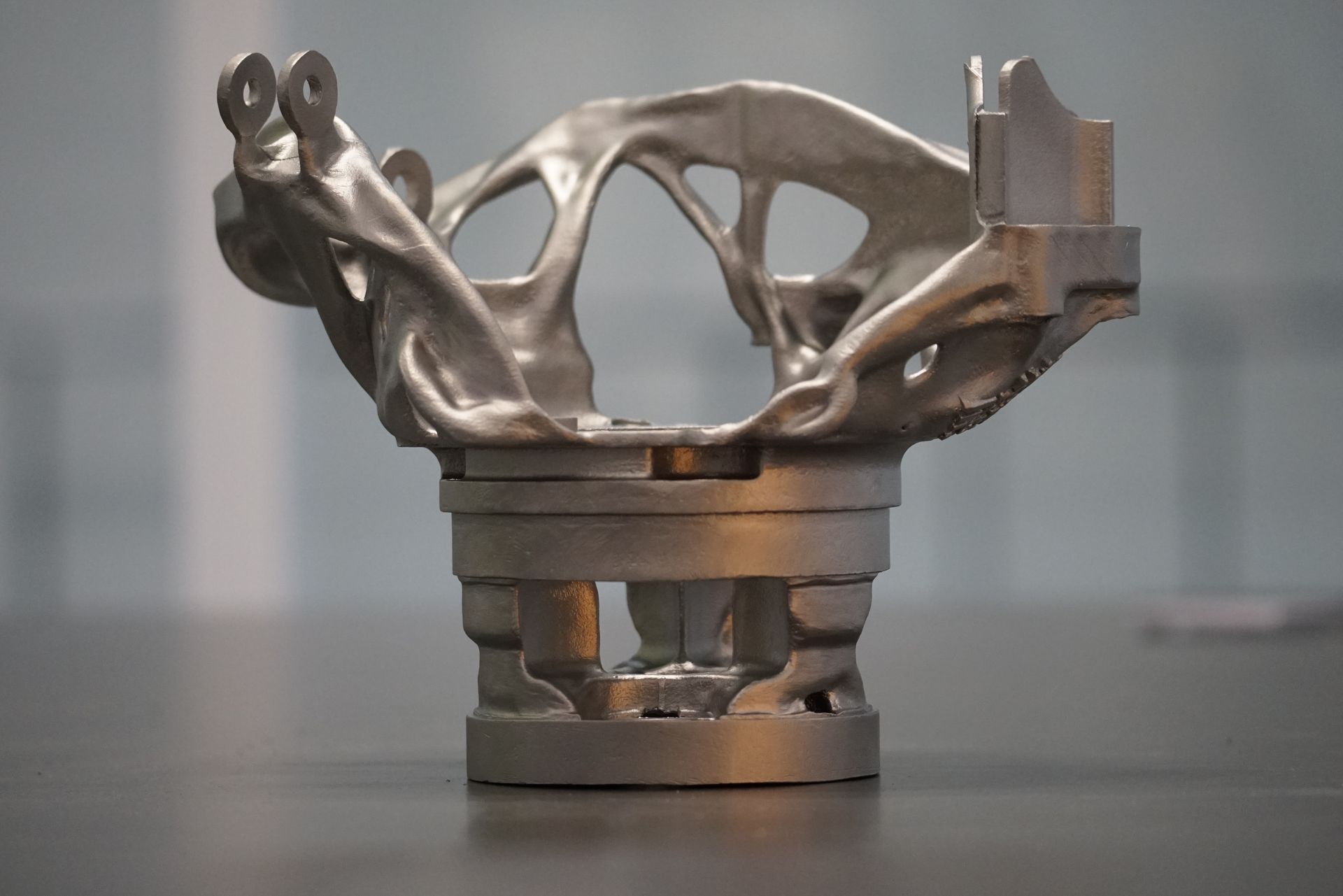

Additive Center introduced a groundbreaking design that consolidated the gripper fingers, springs, and all related parts into one cohesive component. By employing generative design techniques for the initial form, the team then refined the design and its functionality using advanced simulation software. Given the component's critical role, particular focus was placed on the additive manufacturing process to ensure the quality and reliability of the final product were upheld to the highest standards.

Original

The traditional manufactured part was machined, standardized, and assembled using 7 individual components. It features numerous small crevices that require thorough cleaning to remove dirt.

Redesign

The single part redesign significantly improves the hygienic performance, thanks to its smooth surface, which is superior to that of the machined version. Additionally, by incorporating feedback from maintenance managers, the new gripper design has been optimized to reduce both maintenance and assembly time.

The advantages

Reduced costs

We reduced the production costs by half.

Increase Productivity

Extended service lifetime of the gripper enhances productivity.

One part

Consolidated the design and supply chain from 7 parts down to 1.

Easier to clean

The unique rounded top surface ensures better part cleanability.

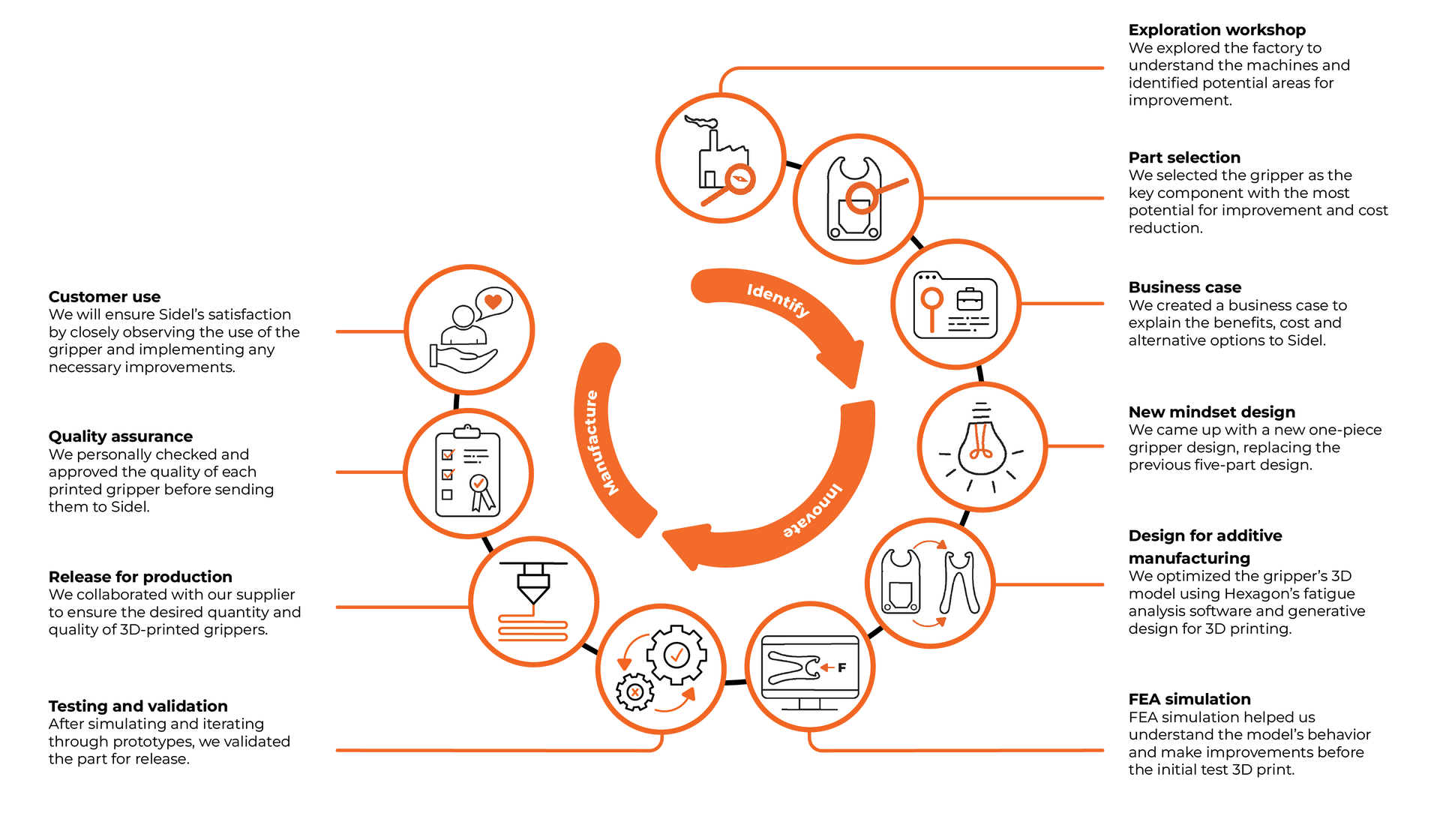

Visual Infographic: A Guide to how we made the Sidel Gripper

This detailed and informative infographic visually represents the various stages and steps involved in our comprehensive project. From the initial planning and research phases to the implementation and evaluation processes, each step is clearly outlined and illustrated, providing a valuable and easy-to-understand overview of the project's progression.

Find out more in this video about the Gripper

Additive Center takes great pride in being a founding member of AMcubator. This ecosystem enables us to collaborate with other top-tier companies to achieve optimal results. What distinguishes AMcubator is our steadfast dedication to delivering tangible business value. From housing leading 3D printing companies to providing cutting-edge equipment in our pilot factory, AMcubator offers a distinctive platform for collaboration and innovation. Our objective? To streamline your AM journey, enhance processes, and ultimately propel scalable applications to market success. Interested in discovering how AMcubator can add value? Click here to learn more.

The following companies contributed to this specific project:

AMsolutions helped us with the surface finish of the metal 3D printed part so that we could achieve a food safe roughness of Ra 0,8 mm

With the help of the fatigue analysis software from Hexagon we could create the generative design of the gripper.

With the cooperation of DiManEx we could create a supply chain analysis and workflow management. We could improve efficiency and reduce the cost even further.

Quality meets affordability. Discuss how 3D printing can be a cost-effective solution for your food packaging needs.

Work with us_gripper

We will get back to you as soon as possible.

Please try again later.